Load Bearing: More Than 40 Tons (can be installed in the middle of the road)

Warranty: 18 Months

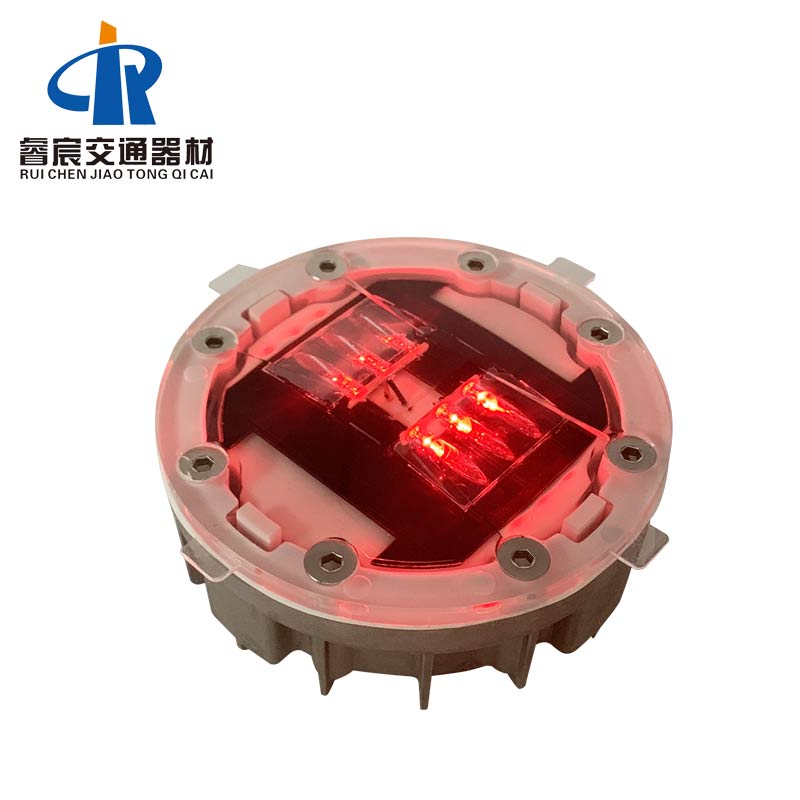

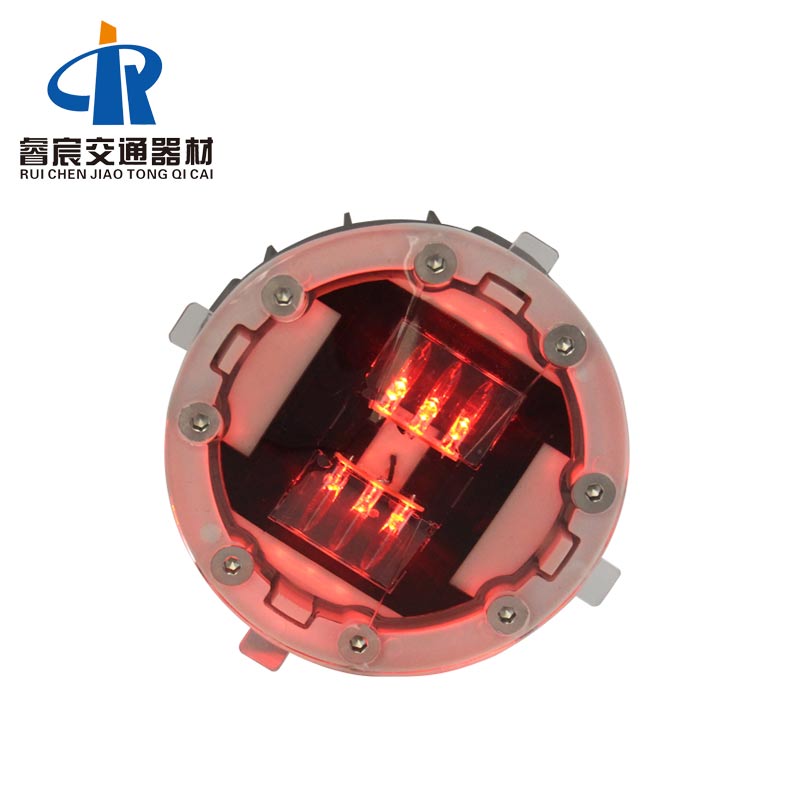

Body material: Aluminium(GB-ADC-12)+PC(Japan Brand)

Power supply: USA Brand Flexible High Efficient Solar Panel

Visual distance: > 800m

Working Mode: Flashing or Constant

Waterproof: IP68

Heavy Duty Solar Road Stud Lights Features:

Aluminum Solar Stud Parameters:

| Material: | Aluminium(GB-ADC-12)+PC(Japan Brand) |

| Power supply: | USA Brand High Efficient Solar Panel 5V/60MA for lithium battery 3V/120MA for super capacitor |

| Battery: | Lithium battery 3.2V/500MA(made in Japan); Supercapacitor 2.3V/120F(made in Korea) |

| Working model: | Blinking or Constant Charging in the daytime and working automatically at night |

| Life span: | 5years for lithium battery; 10years for supercapacitor. |

| Resistance: | > 40T(can be installed in the middle of road) |

| Size: | φ125*50mm (φ4.92″*1.97″) |

| Visual distance: | >800M |

| Water poof: | IP68 |

| Carton Size: | 1pcs/box; 30pcs/ctn; weight: 30kgs; carton size: 67.5*28*20cm 1pcs/box; 30pcs/ctn; weight: 66.14bs; carton size: 26.57″*11.02″*7.87″ |

Application of Heavy Duty Solar Road Stud C2:

♥Schools and hospitals

♥Highways

♥High traffic areas

♥Walking paths

♥Transit stations

♥Parks and campuses

♥Road Center

How to install Aluminum Solar Road Stud C2:

1.Carefully mark the distance between the placement of solar road stud lights. To prevent an adverse effect on the ground, use a proper tool such as Core Drill. Drill 127mm and depth will be 45mm.

2.Remove all debris from the installation hole.

3.Pour epoxy into the holes per the manufacturer’s instruction.

4.Verity that the installation hole is straight. Verify that the installation hole is large enough to allow the epoxy to surround the solar road stud shaft.

5.Set the lighting surface of the Solar Road Stud light to the desired viewing angle. Verify the epoxy is evenly adhering to the installation hole and solar road stud shaft.

After curing the LED solar road stud for 6-8 hours, remove the installation of the isolation facility.